Guide to Disposal of Single-Use Bioprocess SystemsGuide to Disposal of Single-Use Bioprocess Systems

Single-use bioprocess systems can provide a range of environmental benefits beyond those of stainless steel systems. Although single-use systems may generate additional solid waste, benefits include reduction in the amount of water, chemicals, and energy required for cleaning and sanitizing as well as avoiding the labor-intensive cleaning processes required with stainless steel systems (1, 2).

One of BPSA’s core activities is to educate users and develop guides on issues pertaining to single-use systems. The organization’s disposals subcommittee was chartered to establish a guide to address the issue of disposing of single-use bioprocess components and systems. The purpose of this introductory guide is to address the following questions:

What are the options for disposal of a single-use bioprocess component or system?

What are the advantages and disadvantages of each option?

Where can users get more information?

This guide provides information to help concerned professionals and companies better understand the issue of single-use bioprocess component and system disposal.

Options for Disposal

When disposing of a large-scale system, a company may be dealing with an assembly of a 2,500-L bag, connected to several meters of tubing, high area filter capsule(s) — which could be 254 mm (10 inches) or larger— and a connector or perhaps a complex manifold of connectors (3). Various disposal options can be used based on a company’s evaluation and determination of the appropriate method of disposal. In most cases, single-use systems can be disposed of by the same means currently used for process filters, disposable laboratory supplies, and other solid wastes. Factors to consider in planning for disposal include the following:

current practice — in most cases, corporate policy and practices applicable to labware, cleaning supplies, and cafeteria waste will already be established and will probably apply to single-use systems and components.

local firms or agencies — if no applicable policy has been established, contact local environmental or waste management agencies for applicable guidelines and determine whether certified options are available locally.

volume — the volume of solid waste generated will affect the cost and practicality of disposal options.

biohazard — the level of biohazard in the waste may rule out some options.

recyclability — it may be possible to recycle some components of the system after disassembly.

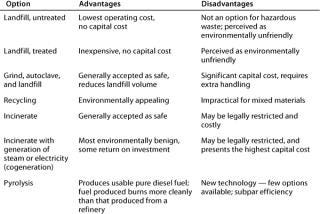

Table 1: At -a-glance comparison of single-use bioprocess system disposal options ()

In general the methods listed in Table 1 can be used. Estimated capital and disposal costs increase as you move down the table.

Table 1: At-a-glance comparison of single-use bioprocess system disposal options

Table 1: At -a-glance comparison of single-use bioprocess system disposal options ()

Landfill Options: Some companies choose landfilling. Its potential as an option varies based on municipality and regional regulations as well as on a product’s use before disposal (4).

Untreated: One industry player landfills an untreated component because its system does not require prior treatment. Another company whose products do not require landfill pretreatment uses biohazard bags before disposal in solid waste trash.

Treated: Based on the application, some companies “kill” the used system or component with a dose of chlorine dioxide or other deactivator and then dispose of the item in a landfill. This option is more expensive than disposing of an untreated component because it requires extra steps before landfilling. It does, however, allow for product to be landfilled after use without other cleaning and decontamination steps.

Grind and Autoclave: Some items are pretreated and shredded before landfilling (5). This option is appealing because it may be accepted as safe in some cases and reduces landfill volume compared with unshredded product. Additional discussions are ongoing regarding use of other hospital waste treatments such as autoclaving, thereby making a single-use system or component suitable for disposal in a standard municipal waste incinerator or landfill (if allowed). Some companies dispose of their used components or systems into a grinder–autoclave currently used at many hospitals, the National Cancer Institute, and the National Institutes of Health, among others.

Landfill technology continues to advance with the development of renewable energy facilities. Biomethane and other landfill gases are environmentally sustainable fuels that can provide alternative energy sources for future generations. Because single-use systems contain insignificant amounts of biomass/organic material, it is unlikely that they will be a source of sustainable fuels with present technology.

Recycling: Recycling is viewed as an environmentally appealing option because it entails collecting materials that would otherwise be considered waste, sorting and processing recyclables into raw materials, and manufacturing raw materials into new products. Recycling is a desirable option especially for products made from a homogenous material.

However, many single-use bioprocess systems are made of multiple materials or layers including polyethylene (PE), polypropylene (PP), ethylene vinyl alcohol, or nylon. Recycling generally is not an option for such products because they require extensive efforts to separate the components into homogeneous components (1). As a result, most single-use systems and components are not amenable to recycling efforts.

Incineration: According to the US Environmental Protection Agency, “incineration is a widely-accepted waste treatment option with many benefits. Combustion reduces the volume of waste that must be disposed in landfills, and can reduce the toxicity of waste” (6). Incineration is a method of disposal that is used in many countries, and some companies incinerate as part of their standard disposal policy. In the European Union, a number of directives specifically address the issue of waste incineration and disposal:

Directive 2000/76/EC of the European Parliament and the Council on the incineration of waste (7).

In some cases incineration also can result in significant energy recovery as discussed below.

Cogeneration is a process in which a facility uses its waste energy to produce heat or electricity. Cogeneration is considered more environmentally friendly than exhausting incinerator heat and emissions directly up a smokestack.

One bioprocess company sends all its waste to a facility that incinerates and uses it to generate electricity for a major US city. Another company uses a waste heat boiler to make low-pressure steam. Although there are wide variations, the heat value of mixed plastics waste is estimated to be about 15,000 to 20,000 BTUs/lb (34,890 to 46,520 kJ/kg), which compares favorably to coal at 9,000 to 12,000 BTUs/lb (20,934 to 27,912 kJ/kg) (10,–11).

Cogeneration is more widely applied in Europe and Asia than in the United States. In the United States, this process is being installed increasingly at universities, hospitals, and housing complexes for which boilers and chillers can serve multiple large buildings. In the European Union, the European Parliament and Council Directive 94/62/EC on packaging and packaging waste, Article 6 addresses energy recovery by incineration, and Article 10 addresses standardization (12).

In addition, the standard EN 13431 Packaging — Requirements for Packaging Recoverable in the Form of Energy Recovery, Including Specification of Minimum Inferior Calorific Value specifies requirements for packaging to be classified as recoverable in the form of energy and sets out procedures for assessing conformity with those requirements. The scope is limited to factors under a supplier’s control (13).

Pyrolysis: Pyrolysis is a method for converting oil from plastics such as PE, PP, and polystyrene (PS) that can be used as fuel for internal combustion engines, generators, boilers, and industrial burners. Plastics are separated into oil, gas, and char residue by being heated in a pyrolysis chamber. Gas flowing through a catalytic converter is converted into distillate fraction by the catalytic cracking process (enzymatically breaking the complex molecules down into simpler ones). The distillate is cooled as it passes through a condenser and then is collected in a recovery tank. From the recovery tank, the product is run through a centrifuge to remove contaminates. The clean distillate then is pumped to a storage tank.

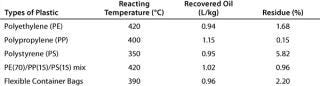

About 950 mL of oil can be recovered from 1 kg of certain types of plastics. A comparison of the distillate produced by pyrolysis and regular diesel shows good similarity between the fuels, with the advantage that distillate from pyrolysis burns cleaner.

Table 2 displays the recovery ratios of the various plastics that can be used with pyrolysis (14).

Table 2: Recovery ratios of plastics used with pyrolysis

Table 2: Re covery ratios of plastics used with pyrolysis ()

Combination of Disposal Methods

Some companies combine disposal methods. For example, one European company classifies waste based on its potential hazard and selects its disposal method correspondingly based on the following system:

red — possible chemical hazard; accumulated on site and sent to a qualified chemical disposal firm

yellow — possible biological hazard; autoclaved on site and sent to an incinerator off-site

white — normal trash; accumulated and sent to incinerator

liquid waste — accumulated and treated on site, sent out for disposal.

Although this discussion of options for disposal illustrates the main attributes of different methods, standards for environmental practices vary by location, country, and region of the world with regard to handling biohazardous wastes, plastic wastes, and waste fluid. We recommend that readers consult their local regulatory agencies before implementing any disposal practices.

How to dispose of single-use components and systems continues to be an issue facing bioprocess companies. Appropriate disposal of single-use systems and components can be part of a process that is environmentally friendly by reducing overall energy consumption as well as chemical and cleaning demands associated with traditional stainless steel systems. BPSA members continue to evaluate options for reducing the environmental impact of single-use components and systems. Future BPSA guides will address disposal options, such as cogeneration, in more detail and will continue to focus on educating users about single-use systems.

REFERENCES

1.) Rombach, C. 2005. Single-Use Benefits and Hopes. BioProcess Int. 3:88.

2.) Cardona, M, and B. Allen. 2006. Incorporating Single-Use Systems in Biopharmaceutical Manufacturing. BioProcess Int. 4:10-14.

3.) 2007. The Irradiation and Sterilization Subcommittee of the Bio-Process Systems Alliance. Guide to Irradiation and Sterilization Validation of Single-Use Bioprocess Systems, Part 2. BioProcess Int. 5:60-70.

4.) Liu, P. 2005. Strategies for Optimizing Today’s Increasingly Disposable Processing Environments. BioProcess Int. 3:10-15.

5.) Scott, C. 2007. ‘Single-Use’ Doesn’t Necessarily Mean ‘Disposable.’. BioProcess Int. 5:4.

6.) U.S. Environmental Protection Agency..

7.) 2000. Directive 2000/76/EC of the European Parliament and of the Council of 4 December 2000 on the Incineration of Waste. Official Journal of the European Communities http://ec.europa.eu/environment/wasteinc/newdir/2000-76_en.pdf.

8.). Council of the European Communities on the Incineration of Hazardous Waste.

9.). Council of the European Communities on Hazardous Waste.

10.) American Chemistry Council PlasticsResource.com: Information on Plastics and the Environment.

11.) Abdullah, G. 2003.Making the Most of a Powerful Nuisance Penn State Agriculture Magazine.

12.) European Parliament and the Council of the European Union on Packaging and Packaging Waste.

13.) British Standards Online.

14.) Ozmotech Pty Ltd (Australia)Ozmotech Energy Technology.

You May Also Like