September 2024

With the first half of 2024 now in the rearview mirror, I finally feel like I’m getting my feet under me as editor in chief of

BioProcess International.

Since the first issue in January 2003, I’ve had the pleasure of helping BPI to establish itself as the leading publication and events brand for the global biopharmaceutical industry. And this September, all the BPI editors will attend our flagship conference and exhibition as part of the Biotech Week Boston festival. We’ll join more than 3200 biotechnology professionals at the Hynes Convention Center to network and share information about advancements across the industry.

Regular readers know the quality of BPI Conference discussions from the reports that we publish. But those are barely the tip of the iceberg. I encourage you to register and attend one or more of the BPI events. Whether in Boston this month; in Kyoto, Japan, this October; in San Diego next March; or in Hamburg, Germany, next May, you have many options to participate as a speaker, exhib...

Historically, the pharmaceutical industry has not been a leader in environmental, social, and governance (ESG) matters. Despite meaningful accomplishments concerning global greenhouse gas (GHG) emissions, our progress on climate action has been slow (

1

). Given the recent focus on sustainability, environmental regulations, and social justice, more pharmaceutical companies are expected to step up and integrate ESG into their short- and long-term strategies. Of course, the related challenges make for a continuous, ever-progressing journey in which milestones and successes stand on the shoulders of previous accomplishments. To achieve meaningful progress and tangible results, ESG must be woven into the fabric of a business.

Companies in the early stages of developing sustainability programs first must determine where to begin — or, at least, begin in earnest. The sheer breadth of ESG can seem daunting, but by taking small steps and establishing appropriate frameworks, companies can achieve positive, substan...

Earlier this year, the RAND Corporation published a report commissioned by US Secretary of Defense Lloyd Austin, which details how current and future biotechnologies can be used as strategies against biological warfare (

1

). The report explains how state and nonstate actors have the ability to weaponize viruses to advance their own interests strategically, even if it impacts both allies and adversaries alike.

The report presents several realistic scenarios, including hypotheticals involving the Chinese and Russian governments using highly contagious airborne viruses to disrupt global stability and further their own aspirations to expand territories:

• The Chinese government might deploy a severe acute respiratory virus to disable US navy operations protecting Taiwan, resulting in military capture of the island in just 46 hours.

• Russia might use a novel, deadly airborne infection with a long asymptomatic contagious period to infect the United States and Western Europe with the goal of taking over former...

Since the 1990s, Chinese hamster ovary (CHO) cell lines have served as the biopharmaceutical industry’s “workhorse” for producing recombinant proteins, especially monoclonal antibodies (mAbs) and derivative formats. Process and product knowledge accumulated over the past 30 years has enabled vast improvements in expression titers and yields. However, development scientists still have much to discover about optimizing cell culture, especially regarding maintenance of product-quality targets for processes involving high-producing cell lines. Aside from selecting clonal cell lines with particularly advantageous characteristics for both quality and yield, upstream teams can experiment with different culture-media compositions and supplementation strategies to control levels of cell growth, protein expression, and metabolite buildup.

While moving through the conference circuit, I have heard many presentations about culture-media development. Often, presenters focus on their teams’ efforts to optimize glucose a...

New-product revenue is the lifeblood of biopharmaceutical companies, providing for growth, financial stability, and investor valuations. However, about half of the new drug products launched over the past 15 years have underperformed compared with prelaunch forecasts by 20% or more (

1

). Assuming that companies perform marketing research to validate their target product profiles (TPPs), the disconnect between forecasts and new products’ postlaunch market performance can be attributed to two factors: Companies overestimate the value of their new product’s differentiation and customer value while underestimating the challenges and time associated with switching patients from products that they already are taking to new drug alternatives.

Forecasting new-product revenues accurately is crucial to managing a biopharmaceutical business. Underperformance disappoints investors and affects portfolio prioritization, clinical investment, and licensing and acquisition valuations. One client told me, “I know I’m over...

Recombinant-protein production is an important process for generating large quantities of biomolecules, including therapeutics, vaccines, and industrial enzymes (

1

). Mammalian cell expression systems — including Chinese hamster ovary (CHO) cells — are often the first choice of host system for biopharmaceutical applications. However, scaling up recombinant-protein production with mammalian cell lines can be time-consuming and costly because they require expensive media compositions, exhibit slow cell growth, and are highly sensitive to shear stresses (

2

). Using microbial hosts to express heterologous proteins allows for increased biomass densities at lower costs because such organisms require less expensive growth media. For example, eukaryotic organisms such as yeasts historically have been popular microbial hosts for recombinant-protein production because of their amenability to genetic manipulation and capacity to perform complex posttranslational modifications (PTMs), including glycosylation and th...

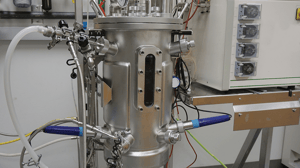

Lessons in Bioreactor Scale-Up: Part 3 — Experimental Determination and Application of Oxygen Mass- Transfer Rate, Mass-Transfer Coefficient, and Oxygen-Uptake RateLessons in Bioreactor Scale-Up — Part 3: Experimental Determination and Application of Oxygen Mass- Transfer Rate, Mass-Transfer Coefficient, and Oxygen-Uptake Rate

The term

mass transfer

refers to movement of a component in a mixture from a region of high concentration to one of low concentration. Transfer can take place in a gas, vapor, or liquid, and it results from the random velocities of molecules (

molecular diffusion

) or from circulating or eddy currents in a turbulent fluid (

eddy diffusion

) (

1

). For example, when a drop of dye is added to water in a container, mass transfer results in the movement of dye molecules through the water until an equilibrium is reached and the dye’s concentration has become uniform. Mass transfer occurs under the influence of a

concentration difference

or

concentration gradient

(a concentration difference over a unit area) in a system.

Many bioprocess steps involve material movement initiated by mass-transfer mechanisms. A well-known example is oxygen supply to fermentation or cell-culture bioreactors: During cultivation, O

2

transfers from sparged air (gas phase) through the gas–liquid interface to the bulk liquid med...

Biomanufacturing platforms based on Chinese hamster ovary (CHO) cells have transformed the industrial production of biologics such as monoclonal antibodies (mAbs) over the past few decades. Despite advances in alternative expression systems (e.g., microbial, insect, other mammalian cells, and cell-free synthesis), the dominance of the CHO platform in the biopharmaceutical industry continues. As the therapeutic protein landscape continues to evolve, the fundamental requirements of biomanufacturing processes remain consistent: An economically viable CHO-based bioprocess requires stably high titers of expressed recombinant protein with controlled product quality (PQ).

Historically, advancements in CHO cell-line productivity have been driven predominantly by process optimization rather than direct genetic manipulation of cells themselves. Early efforts in biopharmaceutical manufacturing focused on refining production parameters such as culture conditions, feeding strategies, bioreactor design, and purificatio...

This case study presents a scenario where a rapidly growing Contract Development Manufacturing Organization (CDMO) was faced with the challenge of expanding their process liquid and buffer preparation capacity to meet rising demand from a client. The sudden increase in campaign volumes resulted in additional capital and operational expenditures, threatening to exceed the site's resources and potentially delay production.

In response, Thermo Fisher Scientific conducted a Process Walk of the company's workflow to identify areas of potential improvement and waste elimination. Key observations highlighted that the limited availability and size of mixing equipment was creating bottlenecks, and inefficient sterile connection technology was resulting in wasted time and additional costs.

To address these challenges, Thermo Fisher proposed their Process Liquid Preparation Services. This solution aimed to maximize productivity and streamline the process liquid preparation steps, enabling the CDMO to meet current an...

Manufacturing chimeric antigen receptor (CAR) T cells involves several key challenges, including high manufacturing costs, unsustainable failure rates, long vein-to-vein processes, and lengthy quality-control (QC) and product-release activities. With support from Sartorius, scientists in the laboratory of Professor Qasim Rafiq (University College London) sought to mitigate these challenges and improve potency and cell yield with intensified production. Intensified production requires scalable, automated bioreactor systems that enable seamless transitions of small-scale models that can be applied for process development in robust manufacturing platforms in large-scale models. The team used the Ambr 250 High Throughput Perfusion system to investigate which process parameters impact CAR-T cell growth kinetics, quality, and functionality.

Experimental Set-Up:

To test CAR-T cell expansion in fed-batch stirred-tank bioreactors, primary T cells were isolated, activated with Dynabeads technology, transduced with...

Empty adenoassociated virus (AAV) capsids pose a significant problem for viral-vector gene therapies. High levels of empty particles can increase patient immune responses while adding no contribution to the clinical efficacy of the treatment. Therefore, efficient characterization tools are needed to quantify empty AAVs. Racha Majed (technical sales specialist at Refeyn) and Quentin Bazot (innovation and process development team leader at ABL) presented a mass photometer for AAV analysis in a January 2024 webinar. The SamuxMP mass photometer enables users to analyze low amounts of samples and calculate empty/full capsid ratios accurately within minutes.

The Presentation

During AAV manufacturing, upstream processes generate some empty capsids. Empty/full AAV capsid ratios are important metrics that should be characterized as soon as possible during process development. Mass photometry enables quick, accurate characterization of such metrics.

Technology Assessment:

ABL scientists compared the SamuxMP mass p...

In 2010, life-sciences company Repligen began to develop its own agarose-based protein A affinity resin. However, work on that resin halted when two critical elements became scarce: high-performance agarose beads and capacity for good manufacturing practice (GMP) production. In 2015, Purolite, an Ecolab company, took on a similar project. Purolite’s challenge was limited access to protein-ligand technology and commercial-scale, GMP-ready ligand manufacturing. Sensing potential for collaboration, Repligen and Purolite codeveloped three affinity resins.

A 2024 Ask the Experts webinar with four representatives from those companies explored the benefits of such technology partnerships. Steve Tingley (vice president of sales) and Jamie Peyser (vice president of fluid management) represented Repligen. Patrick Gilbert (director of research, development, and engineering) and Andrew Masters (head of business development and strategy) represented Purolite.

The presenters discussed evolving needs in the biomanufactu...

Conventional benchtop systems for tangential-flow filtration (TFF) lack the features and functionality of industrial-scale units because they typically are designed for research, testing, and process development, not for manufacturing. As the biomanufacturing industry shifts toward personalized medicine and small-batch therapeutics, companies must rethink bench-scale TFF in applications involving new modalities.

Lucas Smith (product manager at Repligen) presented about the KrosFlo RS 10 TFF system in a recent Ask the Expert webinar. The system is the first automated, bench-scale TFF system built specifically for current good manufacturing practice (CGMP) production. The unit has the same components, controls, and capabilities as a large-scale TFF system used in commercial manufacturing, including all valves, inlets, and outlets for complete end-to-end automation of the entire TFF process, such as buffer and caustic flushing, integrity and permeability testing, ultrafiltration and diafiltration (UF/DF), an...

Scorpius BioManufacturing is a contract development and manufacturing organization (CDMO) based in San Antonio, TX, that focuses on mammalian- and microbial-cell production at the 200-L and 500-L scales. The company specializes in process optimization during phase 1 and phase 2 development to improve a client’s speed to market. Scorpius’s boutique CDMO operations enable flexible working relationships. Joe Payne (president and chief operating officer (COO) of Scorpius) discussed his company’s strengths in a 2024 Ask the Expert presentation.

Scorpius began operations with three objectives: ensuring quality, focusing on science and delivery, and providing scalability. The company’s manufacturing operations span multiple modalities, including protein drugs and cell therapies. Using a broad spectrum of technologies, Scorpius can help clients to expedite timelines by helping to create bespoke production strategies. Focusing on 200-L and 500-L processes enables the company to perform contract work according to l...

The field of cell cryopreservation is introducing transformative approaches to healthcare. It is critical for advancing cellular therapies, regenerative medicine, and biological research. And it is used in organ transplantation and drug discovery, making a broad impact across therapeutic and pharmaceutical sectors.

Cell cryopreservation

is the process of preserving cells and tissues at extremely low temperatures, typically chilled with liquid nitrogen at –196 °C. That enables the long-term storage and transportation of biological samples while maintaining their viability and functionality. Global Market Insights (GMI) predicts that the global cell-cryopreservation market size will exceed US$57.5 billion by 2032 (

1

).

Technological developments have improved cell viability after thawing, improving the efficiency and effectiveness of cell cryopreservation. For example, novel cryoprotectant solutions and automated freezing systems contribute to the viability and integrity of cells upon retrieval. Pluristyx...

Subscribe to receive our monthly print or digital publication

Join our 70,000+ readers. And yes, it's completely free.