thumbnail

Sponsored Content

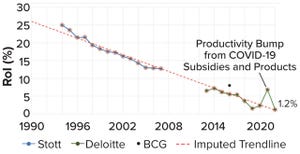

thumbnail

Bioreactors

Characterizing Oxygen Mass Transfer and Shear During Cell Culture: Calculating the Maximum Cell Density Supported By a 20,000-Liter Stirred-Tank BioreactorCharacterizing Oxygen Mass Transfer and Shear During Cell Culture: Calculating the Maximum Cell Density Supported By a 20,000-Liter Stirred-Tank Bioreactor

Sponsored Content

Sponsored Content

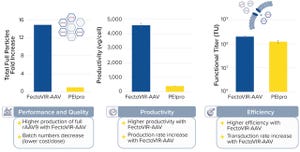

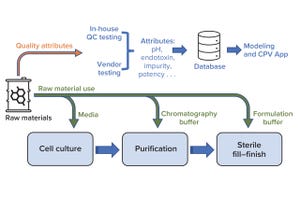

.png?width=700&auto=webp&quality=80&disable=upscale)